Results 11 to 16 of 16

-

02-19-2009, 01:57 AM #11Heli Builder

- Join Date

- May 2008

- Location

- Earth

- Posts

- 288

I am sure you will be able to make the flap gauges out of R/C servo motors.

My PC9M Trim indicators will be made out of 3 x R/C Servo motors (8gram). I already hooked 3 R/C servos to a PIC18F4550 that interface to my PC via USB on the prototype board. See http://www.avcocalc.net/Project/Elec...A/Default.aspx. I was able to move the R/C servos to an exact location. (Disregard the one photo. It shows the Rotary Encoders connected to the board).Fritz -> Helicopter Cockpit Builder

(FSX | TH2Go | Arduino | Air Manager Avionics | CNC)

-

02-19-2009, 03:51 AM #12"Tony"

In memory of Flt Lt Tony Hill who, on 5 December 1941, at the request of Doctor R V Jones, successfully photographed a small "WŁrzburg radar" at Bruneval on the French coast. This from a height of only 200 ft, at high speed, under fire and from a camera mounted obliquely behind the cockpit.

-

02-19-2009, 08:15 AM #13

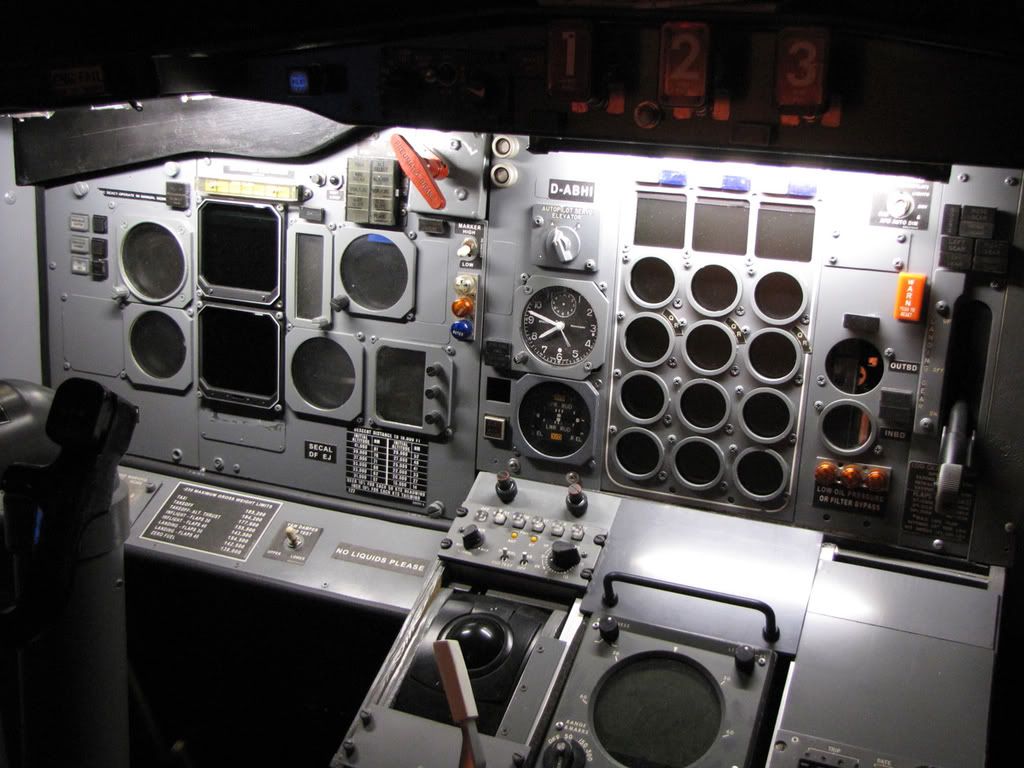

I don't think that would work. It's hard to see in the photo, but the monitor covers 3/4 of the flap gauge mounting holes. To add to the problem, these are both dual needle gauges.

But thanks for the suggestion anyway.

That's what happens when you don't have the correct size monitor for the application.Boeing Skunk Works

Remember...140, 250, and REALLY FAST!

We don't need no stinkin' ETOPS!

Powered by FS9 & BOEING

-

02-19-2009, 08:33 AM #14Heli Builder

- Join Date

- May 2008

- Location

- Earth

- Posts

- 288

-

02-19-2009, 09:21 AM #15

Here's an updated photo with most of the bezels in place except for the EPR and one flap gauge.

All of the missing panel screws have been added too.

Boeing Skunk Works

Boeing Skunk Works

Remember...140, 250, and REALLY FAST!

We don't need no stinkin' ETOPS!

Powered by FS9 & BOEING

-

02-19-2009, 09:32 AM #16

I have seen recently dual needle flap gauges on ebay...??

Just putting the real faceplates and needles would look good (better than Bitmaps)

see if I can trace it back..

http://cgi.ebay.com/ebaymotors/Krato...QQcmdZViewItem

??Jackpilot

B737-700 Posky

FS9/P.Magenta

without PMSystem

Similar Threads

-

Beech Baron Engine gauges?

By Jordan Farmer in forum General Builder Questions All Aircraft TypesReplies: 1Last Post: 09-09-2010, 06:13 PM -

Engine Gauges

By mach7 in forum MyCockpit Support:Replies: 1Last Post: 08-30-2009, 01:32 PM -

How does one make gauges?

By Crescent in forum General Builder Questions All Aircraft TypesReplies: 9Last Post: 07-05-2009, 06:08 AM -

Mechanical engine gauges

By mach7 in forum MyCockpit Support:Replies: 3Last Post: 04-29-2009, 07:25 PM -

How to show only 2 gauges in engine page

By Tony in forum PM Boeing GCReplies: 10Last Post: 11-20-2008, 08:32 AM

Reply With Quote

Reply With Quote

Candid connections: Platform for casual relationships Live Women Prime –°asual Dating

Super –°asual Dating - Genuine...